20th Oct 2021

In the war to reduce carbon emissions, there are few battlegrounds more challenging than the construction industry. Cement and steel manufacture are “hard to abate” sectors that produce a massive proportion of the world’s carbon emissions and other pollutants and yet are crucial for building residential homes, commercial buildings, and public infrastructure.

However, recent innovations in the realm of green hydrogen, and specifically the first shipment of “green steel” made using green hydrogen fuel, have brought new hope to the possibility of “green” construction.

Construction leads the carbon emissions fields

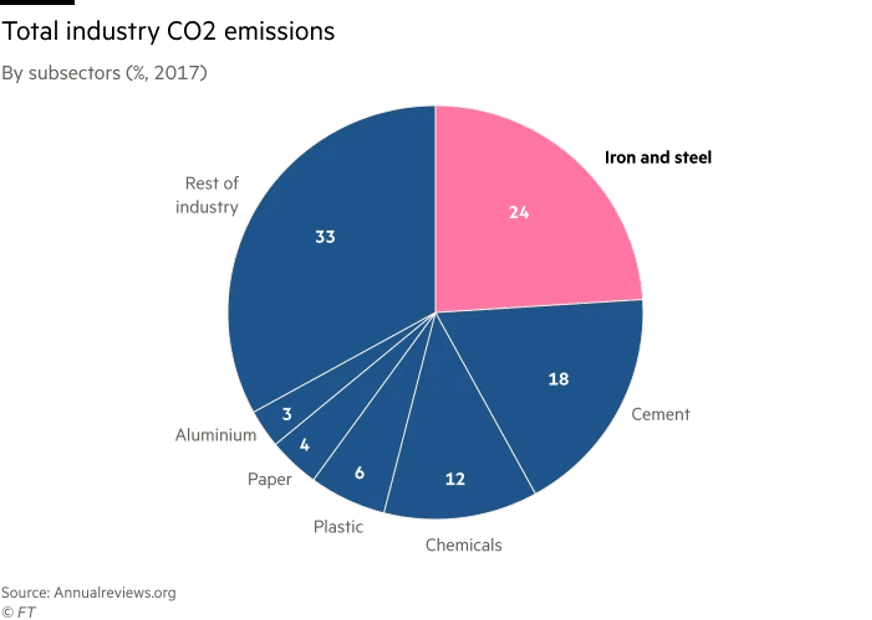

There are many factors driving pollution in construction, including emissions from heavy trucks, and the loss of “carbon sinks”, when areas which absorb CO2 from the atmosphere are destroyed to make space for new buildings. But by far the biggest issue is the carbon emissions released in the production of cement and steel.

Both processes require high temperature furnaces that burn massive amounts of fuel. Consulting firm Roland Berger estimates that the steel industry accounts for 4% of all Europe’s CO2 emissions and 22% of her total industrial carbon emissions1, while McKinsey reports that globally, steel production is responsible for 8% of emissions2. Cement production is no better, producing between 7%3 and 8%4 of global carbon dioxide emissions.

Yet EU member states have committed to cutting greenhouse gas emissions by 55% by 20305, and probably need to revise their targets even more aggressively in light of the most recent UN Climate Change report. There’s no way to meet those goals without urgent decarbonization for heavy polluting industries like cement and steel, but unlike many other high-polluting use cases, these industries need molecule-based fuels and can’t just switch to electrification that draws on renewable energy.

How green hydrogen could help

Green hydrogen offers governments a way to keep climate change promises without dismantling the construction industry. An EU report in 2020 noted that “hydrogen can replace fossil fuels in some carbon intensive industrial processes, such as in the steel or chemical sectors, lowering greenhouse gas emissions and further strengthening global competitiveness for those industries.”6

Hydrogen makes up around 90% of the earth’s atmosphere, present mostly in a compound as water. Electrolyzers separate the hydrogen molecules and send them to pressurized containers, before being transferred into fuel cells so the power can be released as energy when needed. When the process is powered by energy from renewable sources, rather than fossil fuels, the result is termed “green hydrogen”.

As a molecule-based fuel, hydrogen is suitable for industrial feedstock, and it is consistent, sufficient, and cost-effective enough to replace fossil fuels, unlike other renewable energy sources like solar, wind, and biomass.

Green hydrogen may be the last hope for green construction

Admittedly there are obstacles, chiefly the high cost of green hydrogen for steel and cement production. A European Parliament briefing notes that “At current price levels, replacing coal with hydrogen would drive up the price of a ton of steel by about one third.” However, it acknowledges that the price gap is rapidly narrowing and could disappear by 2030, thanks to a combination of the drop in green hydrogen production cost and rising incentives for fossil fuels.7

In a similar vein, a BloombergNEF study predicted that by 2050, green hydrogen could be cheaper than natural gas in some parts of the world8, while a McKinsey report noted that “pure hydrogen-based steel production is expected to be cash cost-competitive between 2030 and 2040 in Europe.”9

Necessity is driving innovation, and the green hydrogen landscape is changing rapidly. Green hydrogen production is rising, with the EU planning to reach 2×40 GW of electrolyzers by 203010 and 23 hydrogen steel projects either underway or close to rollout across Europe in 202111.

Ultimately, in the words of Julio Friedmann, senior research scholar at the Center on Global Energy Policy at Columbia University SIPA, “there are plenty of problems with hydrogen, including scaling up the volumes we need, but that doesn’t matter, it is a must-have.”12

Green steel and cement are on the doorstep

August 2021 saw a breakthrough, when a partnership between carmaker Volvo and the Swedish steel company SSAB to produce decarbonized steel resulted in the first demonstration shipment arriving in August13. “The first fossil-free steel in the world is not only a breakthrough for SSAB, it represents proof that it’s possible to make the transition and significantly reduce the global carbon footprint of the steel industry,” said Martin Lindqvist, President and CEO of SSAB14.

Nor is SSAB alone. Another Swedish venture, H2 Green Steel, is working on a renewable hydrogen plant that can replace coal and coke in the manufacturing process. It aims to produce green steel by 2024, ramping up to 5 million tons of steel per year by 2030.15 In Germany, Thyssenkrupp’s Duisburg steel plant aims to set up its first DRI plant by 2025, using hydrogen or natural gas instead of coke to separate oxygen from iron ore. Thyssenkrupp aims to produce 400,000 tonnes a year of “climate friendly” steel, increasing to 3 million tonnes annually by 2050. The project is incredibly expensive – around €10 billion – but there are hopes that it could turn into the nucleus of a German hydrogen economy.16

The cement industry is only slightly behind. Leading cement producer CEMEX introduced hydrogen to the fuel mix in all its Europe-based cement plants in 2020, and is rolling it out to the rest of global factories this year. Roberto Ponguta, CEMEX Vice-president of Global Operations, Technical and Energy, said “We continue to identify and deploy existing technologies which have a high potential to contribute to our sustainability goals, and hydrogen is a key lever.”17

Finally, Hanson UK, together with researchers at Swansea University, has installed a hydrogen demonstration unit at the Regen GGBS plant in Port Talbot, outh Wales. The Port Talbot Regen GGBS is used as a replacement for up to 80% of the cement in concrete, and has a carbon footprint that is 10% of traditional Portland cement.18

Green hydrogen is already forming the foundations of sustainable construction

With green steel already a reality and green cement coming up quickly, there’s every reason to hope that green hydrogen stocks could help keep the construction industry going without shredding carbon emissions targets.

If you’ve been considering whether to invest in hydrogen, the impact of hydro stocks on construction could form yet another reason to turn to the hydrogen companies stock. An ETF like Defiance HDRO offers a way to spread your exposure to risk across a number of the potentially best hydrogen stocks while taking part in this disruptive technology.

1“EUROPE’S STEEL INDUSTRY AT A CROSSROADS” April 29, 2020 https://www.rolandberger.com/en/Insights/Publications/Europe%27s-steel-industry-at-a-crossroads.html

2 “Decarbonization challenge for steel” June 3, 2020 https://www.mckinsey.com/industries/metals-and-mining/our-insights/decarbonization-challenge-for-steel#

3 “Laying the foundation for zero-carbon cement” May 14, 2020 https://www.mckinsey.com/industries/chemicals/our-insights/laying-the-foundation-for-zero-carbon-cement

4 “Climate change: The massive CO2 emitter you may not know about” December 17, 2018 https://www.bbc.co.uk/news/science-environment-46455844

5 “Climate change: EU leaders set 55% target for CO2 emissions cut” December 11, 2020 https://www.bbc.co.uk/news/world-europe-55273004

6 “COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS” July 8, 2020 https://ec.europa.eu/energy/sites/ener/files/hydrogen_strategy.pdf

7 “The potential of hydrogen for decarbonising steel production” December 2020, https://www.europarl.europa.eu/RegData/etudes/BRIE/2020/641552/EPRS_BRI(2020)641552_EN.pdf

8 “Hydrogen Economy Outlook Key messages” March 30, 2020 https://data.bloomberglp.com/professional/sites/24/BNEF-Hydrogen-Economy-Outlook-Key-Messages-30-Mar-2020.pdf

9 “Decarbonization challenge for steel” June 3, 2020 https://www.mckinsey.com/industries/metals-and-mining/our-insights/decarbonization-challenge-for-steel#

10 “COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS” July 8, 2020 https://ec.europa.eu/energy/sites/ener/files/hydrogen_strategy.pdf

11 “The green edge of steel: Cutting through carbon” June 28, 2021 https://www.whitecase.com/publications/insight/green-edge-steel-cutting-through-carbon

12 “Hydrogen: can the lightest gas turn heavy industry green?” March 19, 2021 https://www.ft.com/content/7a83309e-1dbd-4651-a6fc-52f9be72def7

13 “The First Delivery of ‘Green Steel’ Suggests Its Future Is Not Far Off” August 22, 2021 https://www.sciencealert.com/the-first-deliveries-of-green-steel-suggests-its-future-is-not-far-off

14 “The world’s first fossil-free steel ready for delivery” August 18, 2021 https://www.ssab.com/news/2021/08/the-worlds-first-fossilfree-steel-ready-for-delivery

15 “New Swedish venture eyes fossil fuel-free steel production in 3 years” February 23, 2021 https://www.reuters.com/article/sweden-green-steel/new-swedish-venture-eyes-fossil-fuel-free-steel-production-in-3-years-idUSL8N2KT2ZC

16 “Hydrogen: can the lightest gas turn heavy industry green?” March 19, 2021 https://www.ft.com/content/7a83309e-1dbd-4651-a6fc-52f9be72def7

17 “CEMEX successfully deploys hydrogen-based ground-breaking technology” February 22, 2021 https://www.cemex.com/-/cemex-successfully-deploys-hydrogen-based-ground-breaking-technology

18 “HYDROGEN-POWERED CEMENT PRODUCTION TO REDUCE CARBON EMISSIONS”, February 17, 2021, https://www.springwise.com/sustainability-innovation/property-construction/hanson-hydrogen-powered-cement-production